Food Packaging Equipment in Action: The Complete Packaging Process

What ensures that a bag of flour remains fresh on a supermarket shelf for weeks, or that frozen vegetables reach consumers without losing quality? The answer lies in food packaging. Far from being a simple wrapper, modern packaging is a complex process powered by advanced equipment—designed to safeguard safety, preserve freshness, and optimize efficiency. From the moment ingredients enter the production line to the final pallet shipped to distributors, every stage relies on precision machinery working in harmony. This article explores the complete food packaging process, the critical role of each type of equipment, and why investing in advanced solutions gives food manufacturers a decisive competitive advantage.

The Role and Importance of Food Packaging

Food packaging is far more than a container—it is a critical safeguard that preserves quality, ensures safety, and delivers information to consumers. In the modern food industry, packaging is both a practical necessity and a strategic tool, shaping how products are protected, stored, transported, and perceived in the marketplace.

-

Core Functions of Food Packaging

At its foundation, packaging fulfills several essential roles:

- Preservation and extended shelf life – protecting products against moisture, oxygen, and microbial growth to keep food fresh for longer periods and reduce overall waste.

- Protection from contamination – safeguarding products from physical, chemical, and biological risks. This is especially critical in the food industry, where even minor contamination can compromise safety and consumer trust.

- Communication with consumers – conveying essential information such as nutrition facts, expiration dates, and handling instructions, while also enhancing brand visibility and strengthening consumer confidence.

- Convenience in transportation and storage – allowing bulk movement, efficient stacking, and reduced product waste, while also supporting more sustainable and cost-effective logistics practices.

-

Food Safety and the Role of Automation

The rise of automation has transformed packaging into a cornerstone of food safety and efficiency. Automated equipment minimizes human contact, reduces contamination risks, and ensures consistency across large volumes of production. For manufacturers, this translates into:

- Increasing throughput and production capacity – enabling manufacturers to meet rising consumer demand and adapt quickly to seasonal or market-driven fluctuations.

- Reducing labor dependency and costs – minimizing reliance on manual work, lowering operational expenses, and addressing labor shortages common in the food industry.

- Guaranteeing hygiene and product uniformity – ensuring that every package meets the same high standard, which strengthens brand reliability and consumer trust.

The Complete Food Packaging Process and Key Equipment

The packaging in the food industry involves a sequence of interconnected steps, each supported by specialized equipment. Let’s walk through the five essential phases.

Step 1: Feeding, Cleaning & Sanitizing

Before food reaches its packaging material, it undergoes preparation to meet hygiene standards.

- Feeding Conveyors transport raw or processed food efficiently across the line.

- Washing Machines eliminate dirt, debris, or residues to ensure compliance with safety regulations.

- Air Dryers and Dehydrators remove excess moisture, creating the right conditions for effective sealing and longer shelf life.

The goal of this stage is to deliver clean, safe products into the packaging line while meeting hygiene standards.

Step 2: Forming & Sealing

This step is at the heart of the food packaging process—placing products into packaging and ensuring airtight protection.

The following introduces seven commonly used machines along with their core functions:

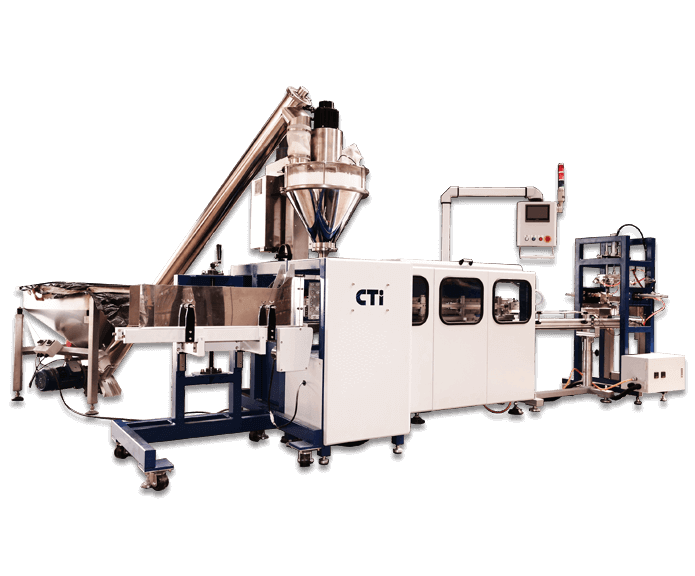

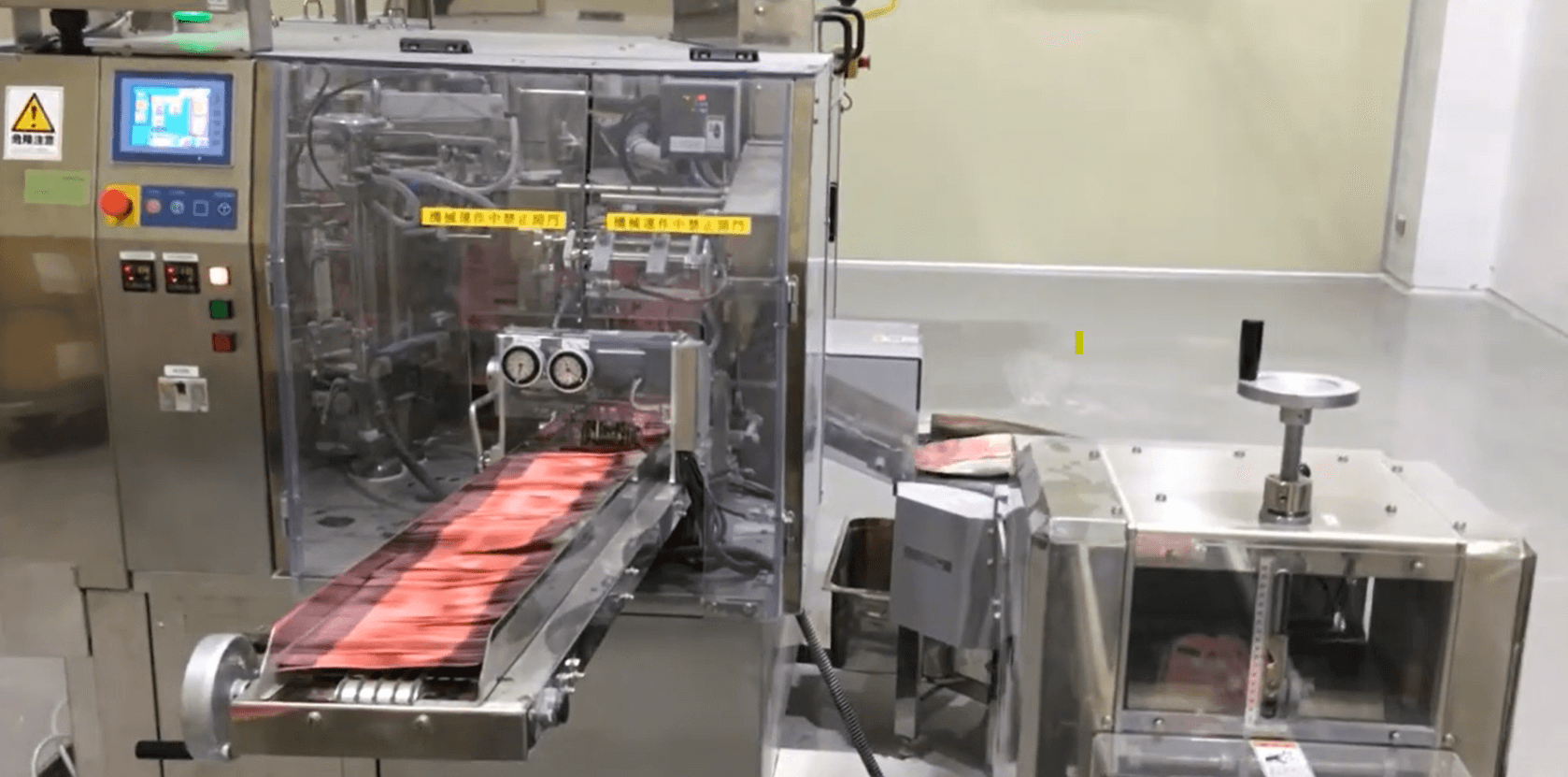

- Bagging Machines – Form bags directly from roll stock, fill them with products, and seal them; ideal for grains, snacks, frozen foods.

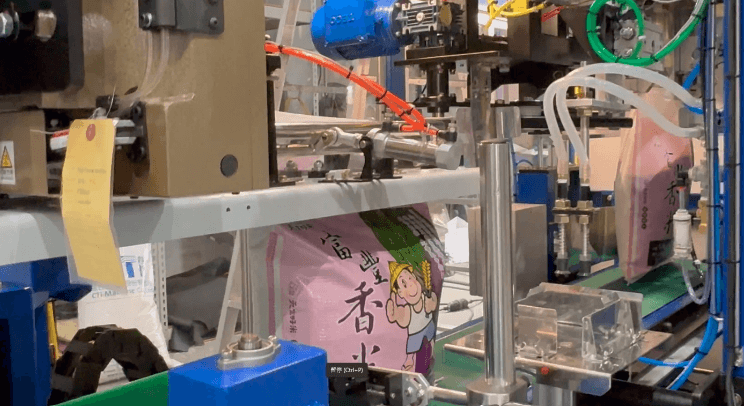

- Premade Pouch Packaging Machines – Handle pre-formed pouches (zipper, stand-up, or gusseted) with precision in filling and sealing.

- Filling Machines – Measure and dispense liquids, semi-liquids, or powders into containers.

- Vacuum Packing Machines – Remove air before sealing, extending shelf life for meat, seafood, and cooked meals.

- Sealing/Seaming Machines – Apply heat-sealing, can seaming, or lid crimping for diverse packaging types.

- Capping Machines – Automatically secure caps on bottles or jars with consistent torque and alignment.

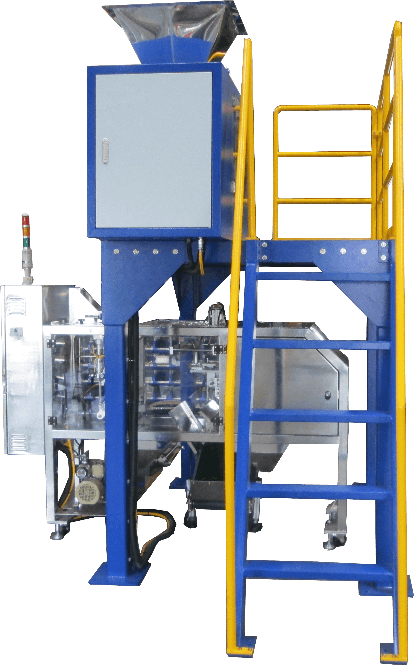

- Bulk Bag Weighing and Packing Machines – Accurately weigh and load large-volume products while maintaining consistency.

The goal of this stage is to secure products in airtight, tamper-proof packaging that preserves freshness.

▲P110T Stand-Up Bag Fully Automatic Packing Machine

Step 3: Labeling & Coding

Beyond protection, packaging must also inform. This stage ensures compliance with regulations and brand visibility, while at the same time enhancing consumer confidence through transparent product information.

- Labeling Machines apply product labels to bottles, boxes, or pouches with accuracy and speed.

- Thermal Transfer Printers & Inkjet Coders mark production dates, lot codes, barcodes, and QR codes for traceability.

The goal of this stage is to provide clear, accurate information for consumers and regulatory compliance.

Step 4: Quality Inspection

To protect brand integrity, defective or unsafe products must be removed before reaching consumers.

- Checkweighers confirm that each package meets weight specifications, preventing underfilled or overfilled products.

- Metal Detectors and X-Ray Inspection Systems identify and reject foreign objects such as metal fragments, glass, or bone, safeguarding product safety.

- Vision Inspection Systems verify seal integrity, label placement, and code readability to maintain consistency and compliance.

The goal of this stage is to ensure product integrity by detecting and removing defective or unsafe items.

Step 5: Secondary & Tertiary Packaging

Once individual products are secured, they are prepared for logistics.

- Shrink Wrapping Machines bundle multiple units with heat-shrink film, ideal for beverages and snack multipacks.

- Case Packers arrange and load products into cartons for distribution.

- Palletizers stack cartons onto pallets in stable configurations.

- Stretch Wrappers wrap entire pallets with film to stabilize loads during shipping.

The goal of this stage is to protect products during handling, storage, and transportation.

Together, these steps illustrate how food packaging goes beyond basic protection—it ensures safety, efficiency, and reliability throughout the entire supply chain.

Key Considerations in Food Packaging Process Design

When designing a packaging line, manufacturers must weigh several factors:

- Level of Automation – balancing efficiency with investment.

- Consumer Trends – adapting to evolving demands like portion packs, resealable pouches, or eco-friendly packaging.

- Sustainability – incorporating recyclable or biodegradable packaging materials.

- Packaging Material Compatibility – ensuring equipment handles flexible films, rigid plastics, paperboard, or glass effectively.

- Quality Control and Traceability – integrating inspection and coding systems for compliance and recalls.

These considerations highlight that successful packaging solutions require more than machinery—they demand strategic alignment with market needs, safety standards, and sustainability goals. Next, we will see a real-world example that illustrates how these principles come to life in practice.

Case Study: Lien Hwa Milling – 1KG Flour Packaging

One example of these principles in action can be seen in the packaging line of Lien Hwa Milling, a leading flour producer. By integrating advanced equipment and aligning with modern packaging priorities, the company successfully achieved both operational efficiency and enhanced food safety.

- High-Speed Output: Advanced bagging and sealing machines allow consistent, large-scale production.

- Flexible Packaging Capabilities: Equipment adapted easily to different flour pack sizes.

- Integrated Safety Checks: Checkweighers and metal detectors safeguarded product integrity and customer trust.

This case demonstrates how strategic investment in food packaging equipment directly translates into higher productivity, better quality control, and stronger consumer confidence.

Conclusion

The journey from raw product to finished package is complex, requiring specialized food packaging equipment at every stage. By investing in automation, manufacturers gain faster production, better hygiene, lower labor costs, and consistent quality.

For food companies to stay competitive, adopting modern packaging systems is essential. That is why CTI stands out as a trusted partner, delivering reliable, flexible, and future-ready solutions for diverse food applications.

Contact Us Today to transform your packaging process for the future.