Guide to Bagging Machines: How They Work and the Different Types

In today’s increasingly globalized business world, packaging has become more critical than ever—not only safeguarding products during storage and transport but also ensuring they are market-ready. Among the wide range of packaging solutions, the bagging machine stands out as one of the most versatile and widely adopted technologies, capable of handling diverse products and meeting the demands of multiple industries.

This article offers a comprehensive guide to bagging machines, covering how they work, their main types, applications across industries, and emerging trends. By gaining a clear understanding of these systems, businesses can make smarter, more strategic decisions when investing in reliable packaging solutions.

What Is a Bagging Machine?

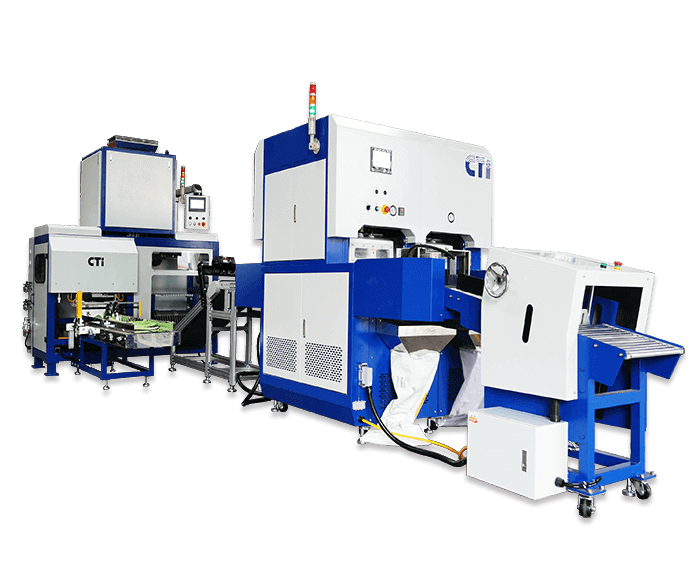

▲Check out our Pre-Made Bag Packaging Machines

A bagging machine is a type of packaging machinery specifically designed to fill products into bags and seal them for storage, transport, or further distribution. Unlike general packaging machines, bagging machines focus solely on the bagging process, making them highly specialized and efficient.

Basic Functions:

- Filling – precisely dispensing a set quantity of product into a bag.

- Sealing – securely closing the bag using heat sealing, stitching, or vacuum sealing.

- Preparation for logistics – ensuring bags are ready for secondary packaging, stacking, or shipping.

Advantages of Bagging Machines:

- Efficiency – capable of packaging large quantities quickly.

- Accuracy – integrated weighing and measuring systems reduce product loss.

- Labor savings – minimize manual handling while improving consistency.

How Bagging Machines Work

Although bagging machines vary in design, most follow a systematic process that ensures precision and consistency:

-

Automatic Feeding and Weighing

The first step in bagging is moving the product into the machine for measurement. Depending on the characteristics of the material—whether it is free-flowing like rice or sugar, granular like fertilizer, or fine powder like cement—different feeding mechanisms are used:

- Gravity-fed chutes: Utilize the natural flow of free-flowing materials for high-speed filling.

- Vibratory feeders: Rely on vibration to move small, lightweight, or fragile particles with precision.

- Screws: Ideal for powders or sticky substances, ensuring controlled and accurate filling.

- Belt conveyors: Used for heavier or irregularly shaped products, allowing smooth and steady feeding.

At this stage, precision weighing systems measure the product before it enters the bag, ensuring that every package contains the exact specified amount. This reduces product loss, avoids customer complaints, and maintains compliance with industry standards.

-

Bag Formation, Filling, and Sealing

Once the product is accurately weighed, it moves into the bagging section. There are two main ways:

- Tubular Film:

This method includes two types: VFFS (Vertical Form Fill Seal) and CTI Machine’s pre-formed tube bag filling system.

- VFFS (Vertical Form Fill Seal)

In the VFFS process, the machine pulls flat film from a roll, forms it into a tube, then performs the following steps:

Flat film → Tube forming → Product filling → Top and bottom sealing

This fully automated process offers high speed and productivity, making it suitable for products such as rice, sugar, and snacks. However, its bag size range is limited—typically one size per machine or a narrow adjustable range.

(Note: VFFS is a common market reference and not part of CTI Machine’s product line.)

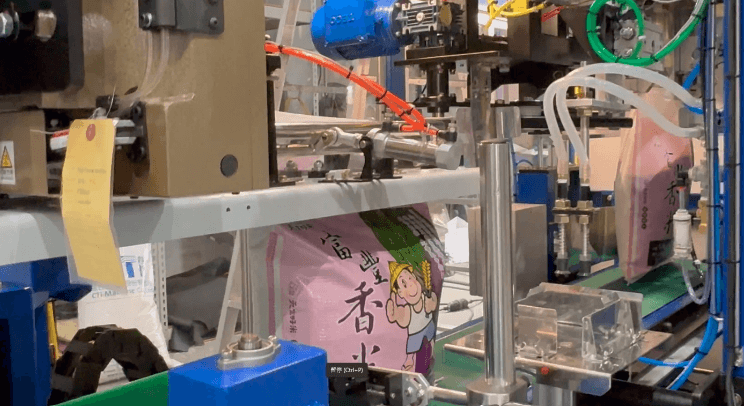

- CTI Machine’s pre-formed tube bag filling and sealing system

CTI Machine specializes in pre-formed tube bag filling and sealing system, which use ready-made tubular bags instead of flat film.

The process works as follows:

Tube bag cutting and first sealing → Product filling → Second sealing

Compared to VFFS, this system provides greater flexibility in bag sizes, lower sealing error rates, and more precise weighing accuracy. It is particularly suited for manufacturers who value packaging quality and consistency.

While the production speed is slightly slower than VFFS, the overall reliability and packaging stability make our solution an excellent choice for diverse product lines. Contact us for more details about Pre-formed Tube Bag Filling and Sealing.

- VFFS (Vertical Form Fill Seal)

- Premade Pouch Machines:

Instead of forming bags from film, these machines use ready-made pouches such as stand-up zipper bags, kraft paper bags, or woven sacks. The system automatically picks up a pouch, opens it, fills it with product, and seals it—either by heat sealing for plastic-based bags or stitching for woven materials. This provides flexibility in packaging styles and is often chosen for premium or retail-ready products.

Sealing is a critical step. Depending on product requirements, different sealing methods may be used, including heat sealing, ultrasonic sealing, or sewing.

- Tubular Film:

-

Integrated Control Systems and Sensors

Modern bagging machines incorporate advanced automation for efficiency and quality assurance. Programmable Logic Controllers (PLC) oversee the entire process, synchronizing feeding, filling, and sealing operations. High-precision electronic sensors detect variations such as improper bag placement, underweight filling, or sealing errors. If an anomaly occurs, the system can stop automatically or alert the operator, minimizing waste and downtime.

Additionally, many machines feature touchscreen Human-Machine Interfaces (HMIs), enabling operators to adjust settings quickly, switch between product types, and run diagnostic checks. This integration ensures not only smooth workflow but also consistent packaging quality across large-scale production.

Common Types of Bagging Machines

Different industries require different bagging approaches. Below are the most common types and their features:

-

Premade Pouch Filling Machines

These systems use ready-made bags such as stand-up pouches, zipper-lock bags, woven sacks, or kraft paper bags. The machine automatically picks up a pouch, opens it, fills it with the desired product, and seals it. This type of bagging solution offers exceptional flexibility in package design, making it an excellent option for companies that want premium presentation or brand differentiation. Industries such as specialty coffee, pet food, and organic grains often rely on premade pouch machines for their ability to handle diverse packaging styles with professional results.

-

Flexible Intermediate Bulk Container (FIBC) Bag Filling Machines

FIBC machines are engineered for bulk packaging needs. They are capable of filling large bags, often referred to as “big bags” or “ton bags,” with weights ranging from several hundred kilograms to multiple tons. Typical applications include cement, fertilizers, sand, resins, and plastic granules. These machines are designed with sturdy frames, dust-control features, and high-capacity weighing systems to handle heavy-duty industrial use safely and efficiently.

-

Vacuum Bagging Machines

Vacuum bagging machines remove air from the package before sealing, significantly extending shelf life and preserving freshness. They are especially crucial in the food industry for packaging perishable products like meat, fish, rice, and processed meals. By eliminating oxygen, vacuum packaging prevents spoilage, inhibits bacterial growth, and enhances storage efficiency. These machines are also valued for reducing package volume, which optimizes storage and transportation costs.

Applications Across Industries

Bagging machines are not limited to one sector—they serve as essential equipment across food, agriculture, construction, chemicals, and pharmaceuticals. By adapting to diverse product characteristics, they ensure efficiency, hygiene, safety, and cost-effectiveness. Below are some of the most notable applications:

- Food Industry

Used for grains, flour, sugar, snacks, and coffee, bagging machines maintain food safety with sanitary designs, dust control, and accurate weighing. VFFS machines pack snacks efficiently, while vacuum systems extend the shelf life of products like coffee. - Agriculture

Seeds, fertilizers, and animal feed require fast, large-scale packaging. Machines in this sector handle abrasive materials with dust extraction and heavy-duty sealing. FIBC bagging systems help farmers manage seasonal surges. - Construction

For cement, sand, and adhesives, durability is key. Valve bagging machines and heavy-duty stitching ensure safe transport of abrasive materials. Automation reduces labor while maintaining consistency in bulk packaging. - Chemicals

Powders, resins, and granules demand accuracy and safety. Machines feature closed systems, anti-static materials, and dust collection to protect workers and products. FIBCs are widely used for bulk and export packaging. - Pharmaceuticals

For powders and additives, precision and hygiene are critical because even the smallest variation in dosage or contamination can affect product safety, efficacy, and compliance with strict regulatory standards. Machines comply with GMP standards, featuring fine dosing, contamination control, and validation to meet strict regulations.

Future Trends and Technological Developments

The bagging machine industry is evolving rapidly to meet global demands for automation, hygiene, and sustainability. Key trends include:

-

Automation and Robotics

Fully automated systems replicate manual handling with greater precision, ensuring higher throughput, consistency, and reduced dependency on human labor. Robotic arms and automated conveyors further improve flexibility in handling different bag types and sizes.

-

Remote Monitoring and IoT Integration

Smart, connected machines enable remote diagnostics, performance tracking, and predictive maintenance. This minimizes downtime, improves efficiency, and supports data-driven decision-making.

-

User-Friendly Interfaces

Modern touchscreen HMIs (Human-Machine Interfaces) simplify setup, operation, and troubleshooting, making machines more accessible even for less experienced operators.

-

Sustainability

Growing emphasis on eco-friendly practices is driving the adoption of recyclable and biodegradable films, energy-efficient sealing technologies, and designs that reduce material waste. Manufacturers are also exploring carbon footprint reduction through modular systems that extend equipment lifespan.

Over the next decade, industrial bagging machines will continue to replace manual labor, ensuring consistency, safety, and cost-effectiveness in packaging lines.

FAQ

Q1: What is the difference between fully automatic and semi-automatic bagging machines?

A: Fully automatic machines handle the entire process—from bag picking to weighing, filling, and sealing—ideal for high-volume production. Semi-automatic machines automate weighing and filling but require manual intervention for bagging and sealing, making them suitable for small-batch, diverse product lines.

▲C5100T Roll Film Fully Automatic Bagging Machine

Q2: Are bagging machines difficult to operate and maintain?

A: Modern bagging machines are designed with user-friendly interfaces. They provide real-time fault alerts and troubleshooting guidance, allowing operators to quickly resolve issues and minimize downtime.

Conclusion

Bagging machines are essential in modern industries, providing efficiency, precision, and labor savings across diverse applications. Whether in food, agriculture, construction, or chemicals, the right bagging machine ensures long-term productivity, consistent product quality, and reduced operational costs.

For businesses ready to optimize their packaging processes and stay ahead of the competition, explore CTI’s fully automatic packing machines today and transform your production line into a model of efficiency and reliability. Contact Us Now!