Guide to Packaging Machinery: What is it and its Types

In today’s fast-paced manufacturing environment, packaging plays a critical role in product presentation, preservation, and distribution. Efficient packaging is not only about aesthetics but also about maintaining product quality and ensuring safety. As production volumes increase, the speed and consistency of packaging processes have become essential for operational success. This is where packaging machinery comes into play, transforming manual tasks into streamlined, automated solutions that reduce error, enhance productivity, and cut down on labor costs.

What is Packaging Machinery?

Packaging machinery refers to a broad range of equipment used in the packaging process of products. These machines are designed to handle various tasks such as filling, wrapping, sealing, labeling, and boxing, among others. They are categorized based on their level of automation:

-

Manual Packaging Machines:

Require significant human intervention and are suitable for small-scale operations.

-

Semi-Automatic Packaging Machines:

Combine manual handling with automated operations, ideal for medium-scale businesses that need flexibility.

-

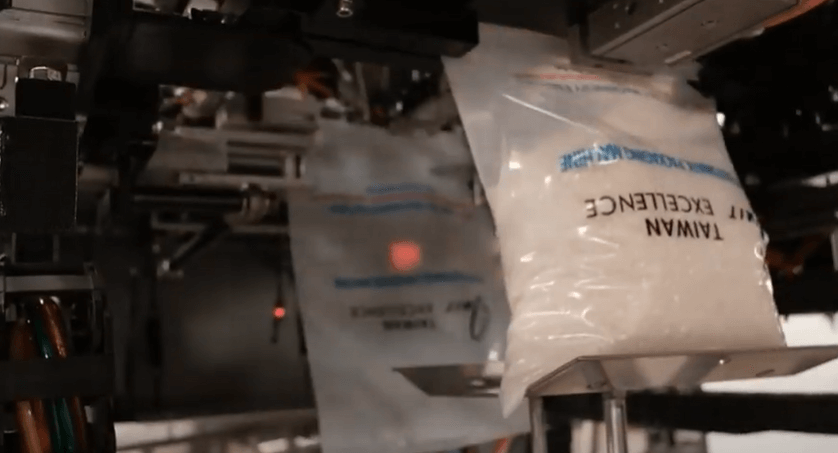

Fully Automatic Packaging Machines:

Operate with minimal human input, significantly reducing the need for labor. These machines improve quality control by minimizing human error and are especially beneficial in industries facing labor shortages.

For businesses aiming to scale operations efficiently and sustainably, upgrading to automated packaging solutions is a strategic move that offers long-term benefits.

Common Components and How Packaging Machinery Works

Before selecting a machine, it’s important to understand the typical components that make up packaging equipment. These elements form the foundation for how different machines operate across various applications.

- Feeding System: Dispenses the product accurately into the machine.

- Conveying System: Transports items through various stages of packaging.

- Sealing Unit: Applies heat or pressure to seal packages securely.

- Control Panel: Allows operators to set and adjust parameters for precision.

In automated systems, these components are integrated using sensors, actuators, and programmable logic controllers (PLCs). These technologies allow real-time monitoring, ensure precision, and enable consistent operation. Automated coordination between components reduces the need for manual labor, enhances product quality, and minimizes downtime, making these systems highly efficient and reliable.

Types of Packaging Machinery

There are various types of packaging machines, each designed for specific tasks:

-

Filling Machines:

These machines are used to accurately fill liquids, powders, or granules into containers. They are essential in industries like food and beverage, pharmaceuticals, and chemicals, where precise measurements are critical.

-

Wrapping Machines:

Wrapping machines wrap products in a protective layer of film or paper. This extra layer of protection is commonly used for electronics, food items, and other delicate goods to prevent damage during transport.

-

Sealing Machines:

Sealing machines are used to securely seal bags, pouches, or bottles, ensuring product safety and freshness. They are indispensable in food packaging and other industries that require airtight or tamper-evident packaging.

-

Labeling Machines:

Labeling machines automatically apply labels to packages, improving labeling speed and consistency. They are essential for branding, regulatory compliance, and providing consumers with important information.

-

Shrink Wrapping Machines:

These machines use heat to shrink a layer of plastic film tightly around the product, creating a tamper-evident, protective barrier. This type of packaging is often used for retail products, multipacks, and promotional bundles.

-

Vacuum Packaging Machines:

Vacuum packaging machines remove air from the package to extend the shelf life of products. This method is particularly useful for food and electronic products, helping to preserve quality and freshness.

-

Cartoning Machines:

Cartoning machines automatically pack items into cartons or boxes, streamlining the packaging process. They are widely used in the pharmaceutical, cosmetics, and food industries for their efficiency and consistency.

-

Bulk Bag Fillers (FIBC Filling Machines):

Also known as bulk bag fillers or ton bag filling machines, these are designed to efficiently fill large bags—often called FIBCs (Flexible Intermediate Bulk Containers)—with powders, granules, or other bulk materials. They are essential for handling products in industries such as agriculture, mining, chemicals, and construction.

Applications of Packaging Machinery and the Benefits of Automation

What are the benefits of using packaging machinery? When upgraded to automated systems, these machines bring significant advantages: better hygiene, higher efficiency, and reduced reliance on manual labor.

Let’s take a closer look at how different industries apply packaging machinery and the added benefits of automation.

- Food Industry:

Packaging machinery is essential for products like flour, spices, and grains. Automated systems ensure hygienic processing and boost production efficiency, meeting demand while maintaining food safety standards. - Pet Products:

For packaging pet food and feed, automated packaging systems reduce the need for manual handling and improve consistency and filling accuracy. - Agricultural Products:

Fertilizers, pesticides, and soil are commonly packaged using automated systems. Automation helps increase productivity while significantly reducing labor costs. - Pharmaceutical & Chemical Industry:

In industries that handle medicines and plastic granules, automated packaging ensures precision, safety, and compliance with strict hygiene standards. - Construction Materials:

For heavy materials like sand and cement, automated packaging machinery addresses the challenges of labor-intensive handling, making the process safer and more efficient. - Electronics:

Secondary packaging provides crucial protection for delicate electronic devices during storage and transportation, reducing the risk of damage caused by impact, moisture, or static electricity.

Future Trends and Technological Developments

The packaging industry is rapidly evolving, driven by advances in automation and technology. Here’s what’s on the horizon:

- Smart Automation:

Integration of AI and IoT technologies enables real-time monitoring, remote control, and predictive maintenance. This reduces downtime and ensures consistent packaging quality. - Labor Reduction:

Robotics and full automation help overcome workforce shortages and lower the risks of human error. - Enhanced Quality Control:

Sensors and data analytics ensure precise and consistent packaging standards, improving traceability and product safety. - Sustainability and Efficiency:

Automated systems help standardize packaging materials, reduce waste, and optimize resource use.

By upgrading to these advanced packaging solutions, industries can achieve faster production rates, better quality assurance, and long-term cost savings, while also adapting to future trends and environmental goals.

FAQ

Q1: What is the difference between fully automatic and semi-automatic packaging machines?

A: Both machine types can perform accurate measuring and filling. However, fully automatic machines also handle bag forming, sealing, and labeling with minimal human involvement, aligning with modern automation trends.

Learn more about our high-performance auto packaging machines.

Q2: What are the machines used in packing?

A: There are several essential types of packaging machinery that support various industries by improving efficiency, safety, and product presentation. These include:

- Filling Machines

- Wrapping Machines

- Sealing Machines

- Labeling Machines

- Shrink Wrapping Machines

- Vacuum Packaging Machines

- Cartoning Machines

- Bulk Bag Fillers

These machines perform tasks like filling, sealing, labeling, and wrapping, helping to streamline the packaging process and maintain product integrity across various industries.

CTI’s Commitment to High-Performance Packaging Solutions

Packaging machinery is essential in modern production, ensuring product quality, consistency, and operational efficiency. As industries expand, automating packaging processes becomes crucial for reducing labor demands and meeting growing market needs. Investing in advanced packaging solutions not only minimizes errors and labor costs but also guarantees long-term reliability and adaptability.

For businesses looking to elevate their operations, CTI offers cutting-edge equipment engineered for superior automation, precision, and durability. Contact us today to discover how our packaging solutions can help streamline your production and drive your business forward.