What is Secondary Packaging: Definition and Examples

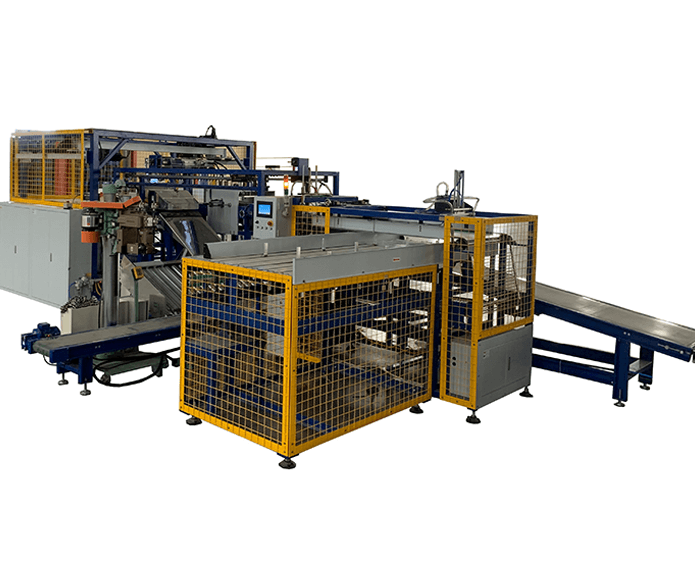

▲ CTI Machine’s D800T Automatic Secondary Packing Machine

Packaging plays a crucial role in protecting products, enhancing branding, and improving logistics efficiency. By ensuring goods remain intact during transportation, it helps reduce damage and waste. In many industries, secondary packaging examples—such as boxes, cartons, shrink wraps, and outer labels—demonstrate how effective packaging can streamline handling and storage.

At the same time, well-designed packaging strengthens brand recognition, attracting customers and influencing purchasing decisions. Effective packaging not only preserves product quality but also boosts customer satisfaction, making it a key factor in overall business success.

What is Secondary Packaging?

Secondary packaging is the second layer of packaging used in the product distribution process. Unlike primary packaging, which directly contains and protects the product, secondary packaging is used to group multiple units of a product together. Its main functions are to provide additional protection, simplify handling, and make storage and transportation more efficient.

Common types of secondary packaging include cardboard boxes, shrink wrap, trays, and display cartons. For example, while an individual bottle of water has its own plastic container (primary packaging), a six-pack wrapped in plastic film or placed in a cardboard carrier represents the secondary packaging. In retail settings, it's also used to create shelf-ready packs that make product display easier.

Beyond its logistical role, secondary packaging often serves as a marketing tool. Brands use it to showcase logos, product information, or attractive designs that catch the consumer’s eye. In short, secondary packaging plays a crucial role in the supply chain, bridging the gap between manufacturing and the retail environment, ensuring products arrive safely and are presented effectively.

Functions of Secondary Packaging:

- Branding and Identification: Enhances brand visibility and provides space for essential product information.

- Additional Protection: Helps protect the primary package from external damage, ensuring safe storage and handling.

- Efficient Transportation: Makes it easier to transport multiple items in a consolidated format, reducing logistics costs and improving efficiency.

Common Secondary Packaging Equipment

To streamline the packaging process, various machines are used in secondary packaging operations.

Some of the most common types include:

- Carton Erectors and Sealers: Used for assembling and sealing boxes efficiently.

- Bagging Systems: Automates the process of placing products into protective bags.

- Robotic Palletizers: Use robotic arms to stack and arrange packaged products for optimal storage and shipping.

Main Types of Secondary Packaging

There are several types of secondary packaging, each serving specific functions:

- artons: One of the most widely used forms of secondary packaging, offering excellent storage and transport convenience.

- hrink Wrap: Commonly used in retail to bundle multiple products together, providing a compact and tamper-resistant solution.

- isplay Boxes: Designed for direct placement on retail shelves, increasing product visibility and accessibility for consumers.

Applications of Secondary Packaging

Secondary packaging is widely used across a broad range of industries, serving both functional and marketing purposes. It not only ensures product protection during transit but also enhances presentation and brand visibility on shelves.

A common secondary packaging example is the use of cardboard cartons to group individual items together for easier handling and display.

● Food & Beverage:

Multi-pack cartons for bottled drinks facilitate bulk handling, efficient transportation, and attractive retail displays. This type of packaging also improves shelf organization and product visibility in stores.

● Electronics:

Secondary packaging provides crucial protection for delicate electronic devices during storage and transportation, reducing the risk of damage caused by impact, moisture, or static electricity.

● Pharmaceuticals:

Outer cartons safeguard medications while offering space for essential labeling and regulatory information, such as dosage instructions and expiration dates. Packaging materials must comply with strict industry standards, including light exposure and tamper-evidence requirements.

● Cosmetics & Personal Care:

Premium and aesthetically designed secondary packaging enhances brand image and consumer appeal, often influencing purchasing decisions at the point of sale.

● Agriculture:

In the agriculture sector, secondary packaging like stretch-wrapped pallets or boxed units is used to bundle bags of soil, fertilizer, and mulch. This improves handling, protects contents from moisture or spillage, and ensures safer, cleaner transportation.

By meeting both practical and branding needs, secondary packaging adds significant value throughout the supply chain.

Future Trends in Secondary Packaging Machinery

The secondary packaging industry is rapidly evolving with technological advancements, driven by the growing demands for efficiency, sustainability, and precision in modern production environments.

- Automation and Robotics: The integration of intelligent automated systems and robotic arms significantly enhances production speed, accuracy, and flexibility while reducing labor costs and human error. These systems enable faster changeovers and real-time adjustments, making them ideal for high-mix, low-volume production environments.

- Standardization of Packaging Materials: The trend toward standardized and modular packaging materials supports sustainability goals by simplifying recycling processes, reducing material waste, and lowering environmental impact. It also helps companies meet global packaging compliance regulations more easily.

- Quality Control Optimization: Modern secondary packaging lines now incorporate advanced inspection technologies, such as machine vision and sensor-based systems, to detect defects, monitor sealing integrity, and ensure labeling accuracy. These improvements lead to consistent product quality and greater consumer trust.

Why Choose CTI Machine’s Secondary Packaging Machines?

With over 40 years of development experience, CTI Machine specializes in developing, designing, and producing customized packing machines. We have developed a full range of packaging machine integration technologies to meet the diverse needs of different industries. Our expertise allows us to design customized secondary packaging solutions that enhance efficiency, precision, and production speed.

FAQ

Q1: How can I improve the efficiency of my production and packaging line?

A: Implementing CTI Machine’s secondary packaging machines allows for batch processing, real-time traceability, and enhanced quality control. Our automated solutions streamline production, reduce labor costs, and ensure consistent packaging quality.

Q2: What is the difference between primary and secondary packaging?

- Primary Packaging: Directly contacts the product, serving as the first layer of protection. Examples include plastic wrappers for food, beverage bottles, and pill containers.

- Secondary Packaging: Encloses the primary package for extra protection, branding, and logistical convenience. Examples include multi-pack cartons, toothpaste boxes, and snack cases.

Maximize Efficiency with the Right Secondary Packaging Machine

Secondary packaging plays a vital role in modern manufacturing by providing product protection, enhancing brand visibility, and improving logistics. As automation technology advances, businesses can significantly boost efficiency with cutting-edge secondary packaging systems.

CTI Machine offers a complete range of secondary packaging machines designed to streamline your packaging process and ensure consistent, high-quality output. With packaging capabilities ranging from 100g to 1000kg and precise weight control, our solutions cater to a wide variety of production requirements.

Contact us to learn how our machines can optimize your production.